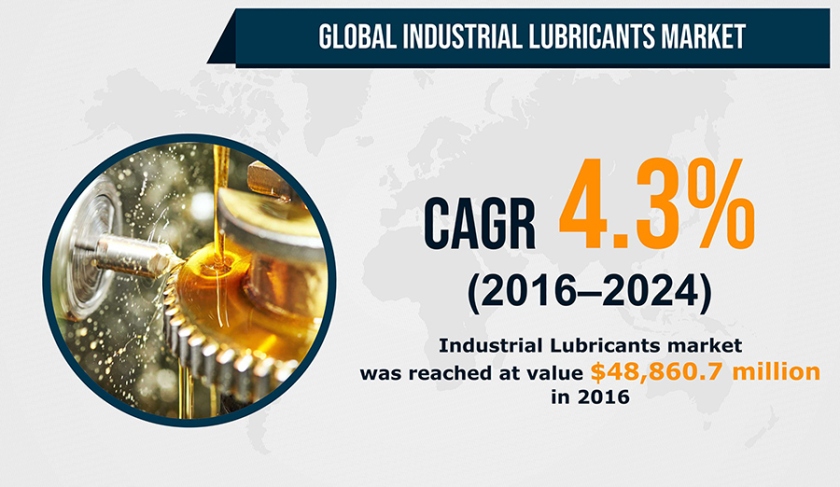

Chemical oils are produced to optimize the operating life and performance of the equipment, which withstand extreme stress during the production of nitrogen fertilizers, especially in terms of temperature, pressure, and compatibility with ammonia and catalyst. On a global ground, the APAC region is anticipated to lead the industrial lubricants market during the 2016–2024 period. This is attributed to the rapid industrialization in India, China, and Southeast Asia along with the modernization of machinery across industries.

Global Market Size and Forecast

5.1 By Product

5.2 By Application

5.2.1 Metalworking by Type

5.2.1.1 Metal forming by metal type

5.2.1.2 Metal cutting by metal type

5.2.1.3 Metal joining by type

5.2.2 Textile by Type

5.2.2.1 Textile finishing by type

5.2.3 Energy by Type

5.2.4 Chemical Manufacturing by Type

5.2.5 Food Processing by Type

5.2.5.1 Canned food by type

5.2.6 Hydraulic Machinery by Type

5.3 By Region

Manufacturing sectors such as paper and mill, foundry, metal forming, food and beverages, and machinery are increasingly using industrial lubricants. Due to the debt crisis in Europe and economic recession in North America, the global industrial output witnessed a fall in 2008 and 2009. However, the manufacturing industry of developing nations, such as China, Indian, Brazil, Russia, and South Africa remained unaffected. The industrial production in these countries witnessed a rise during 2008–2009, and the growth is expected to continue during the forecast period .

Chapter 6. North America Market Size and Forecast

6.1 By Product

6.2 By Application

6.2.1 Metalworking by Type

6.2.1.1 Metal forming by metal type

6.2.1.2 Metal cutting by metal type

6.2.1.3 Metal joining by type

6.2.2 Textile by Type

6.2.2.1 Textile finishing by type

6.2.3 Energy by Type

6.2.4 Chemical Manufacturing by Type

6.2.5 Food Processing by Type

6.2.5.1 Canned food by type

6.2.6 Hydraulic Machinery by Type

These oils are used as a processing aid or as a raw material in multiple end-use industries, such as chemicals, plastic, and rubber. These lubricants are witnessing huge demand in the Asia-Pacific (APAC) region due to the expanding chemical industry, which is expected to boost the market. Industrial lubricants find wide-ranging applications in industries including metalworking, energy, chemical manufacturing, textile, food processing, hydraulic machinery. Among these, in 2016, the chemical manufacturing industry held the largest (over 20.0% sales volume share) in the industrial lubricants market and would continue dominating it during the forecast period.